Look out the window. Chances are you are going to see something made using cement. Cement is a key component in concrete and is the second most consumed product globally after potable water. The industry has been widely identified as a key sector to decarbonize as it accounts for an estimated 8% of global greenhouse gas (GHG) emissions. If we take the example of a standard building constructed using concrete, about 40% of the embodied emissions (non-operating) can come from the concrete supply chain alone.

Cement: A primer

The production of cement is where the bulk of concrete’s emissions are derived from. At a high level, the process involves mixing limestone (calcium carbonate) and clay while being heated to high temperatures (~1500℃), typically using fossil fuels. This mixture is then cooled to form ‘clinker’ which acts as the ‘glue’ in cement. Clinker is then ground together with additives, typically gypsum and supplementary cementitious materials (SCMs) such as fly ash, to form cement. SCMs, when available to the cement plant, are typically waste materials that are used as filler. The entire process generates CO2 as the calcium carbonate is chemically altered through the burning of fossil fuels to heat the mixture, which can be seen in the following graphic:

Heavy industry is recognizing the need for decarbonization and this is reflected in newly-announced net-zero commitments by large players such as CEMEX and Heidelberg in addition to the formation of the World Business Council for Sustainable Development (WBCSD) by the Global Cement & Concrete Association (GCCA). This has culminated in a large number of startups aiming to develop technologies to support the industry’s decarbonization effort. These approaches typically range from using renewables to generate heat, electrochemical approaches to making cement, carbon capture at the kiln, improving a particular SCM, and even sequestering CO2 at the time of mixing the concrete. Clean Energy Ventures’ (CEV) analysis and discussions with various industry participants suggests that a key challenge that many of these startups struggle with is cost sensitivity, either with new feedstocks or in operating the modification. This is also closely interrelated with the need for easy utilization in existing construction processes, as the cost of switching materials is often prohibitive. In some cases, while the innovation may address the previous concerns, there is very limited CO2 impact or performance benefit and not enough incentive for cement manufacturers.

Given this competitive landscape, CEV was excited to learn of Carbon Upcycling Technologies flagship technology, which embeds CO2 into a variety of materials to be used as SCMs. With Carbon Upcycling, cement manufacturers can reduce the carbon intensity of concrete by 30 percent today, and utilize a variety of new materials as feedstocks to replace clinker with SCMs to significantly reduce supply chain emissions. Carbon Upcycling’s technology extends beyond cement with applications in plastics and a newly-launched consumer brand, Oco. CEV recently led a $6M financing in the company, with participation from CEMEX Ventures, the corporate venture capital of CEMEX, Amplify Capital, a leading impact venture fund that invests in early-stage startups addressing the world’s most complex and urgent problems, and Oxy Low Carbon Ventures (“OLCV”), a subsidiary of Occidental (“Oxy”) focused on advancing cutting-edge, low-carbon technologies and business solutions. The round includes participation from Zero Carbon Partners, Purpose ESG, Clean Energy Venture Group, Fund for Sustainability and Energy, Prithvi Ventures, Bryan Trudel, and Mark and Faye McGregor.

Leveraging SCMs to decarbonize cement

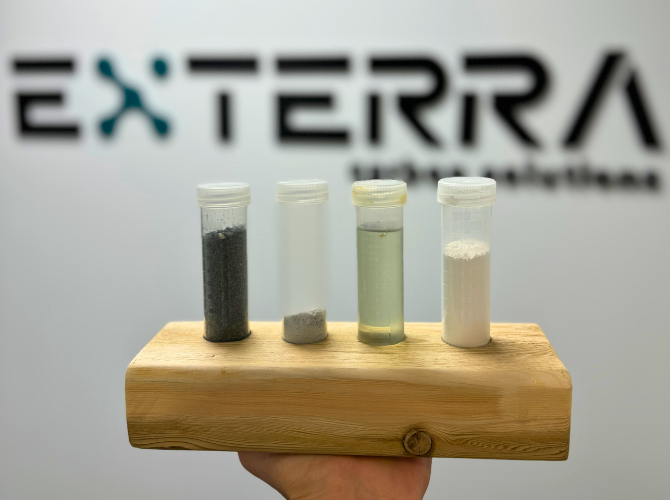

SCMs have been used historically as an additive by the cement industry due to their lower cost and slight performance benefits. Carbon Upcycling’s innovation works by taking existing SCM feedstocks and placing them in a CO2 filled reactor along with their proprietary catalyst, which allows the CO2 to enhance the material. The resulting enhanced SCMs have demonstrated significant performance improvements in the resulting cement, such as a 40 percent improvement in strength and significantly improved durability and climate resilience. Additionally, this has an impact on emissions in two ways, firstly by sequestering CO2 in the feedstock and therefore in the cement, and secondly, by allowing cement manufacturers to reduce the amount of clinker in the cement which significantly lowers the carbon intensity of the end product. This can cost-effectively help customers achieve their net-zero goals. This ability can be further enhanced: Carbon Upcycling is targeting using flue gas from industrial sources, such as directly from a natural gas plant or from cement kilns’ emission stacks, as the source of the CO2 that is sequestered.

Traditional SCMs (such as fly ash and blast-furnace slag) account for only 15% of current cement production with scope to increase to 30-50%. Although the usage has been growing, there are some factors that are still limiting their usage. One factor has been the challenge of cost-effective logistics as in many instances the SCMs are not locally available to the plant and have to be transported (sometimes across the globe). Another factor that has limited the usage of SCMs is the availability of fly ash and blast furnace slag. As we move away from using coal and increase the recycling of steel this scarcity is only going to increase.

One of Carbon Upcycling’s greatest strengths is the flexibility it provides as they have demonstrated the ability to use a variety of feedstocks, including naturally occurring sediments, and enhancing them to use as SCMs. They have demonstrated this so far with over two dozen different types of materials, and this flexibility allows customers to source abundant materials more locally and significantly reduce the carbon intensity of the supply chain. Carbon Upcycling’s technology has demonstrated promise with feedstocks local to both regions.

Strong foundation: a dynamic team building success

The Carbon Upcycling team is incredibly tenacious and comprises go-getters that have bootstrapped their way to significant traction reflected in their agreements with multiple cement producers and participation of CEMEX in the investment. With CEO Apoorv Sinha at the helm, the team has already deployed several reactors in the field and aims to use the funding to scale the company and reactor sizes. Apoorv, a chemical engineer recognized on Forbes’ 30 Under 30 list, has demonstrated incredible leadership in both catalyzing the company’s growth and in the development of the technology. A young, dynamic, and growing team has consistently learned new skill sets in its evolution, from learning to procure heavy machinery equipment and working in coveralls to negotiating agreements with some of the largest players in the cement industry.

This is Clean Energy Ventures’ first investment in the carbon-to-value space and with Carbon Upcycling we believe there’s a path to reduce over 2.5Gt of GHG emissions in one of the hardest to decarbonize sectors. We’re looking forward to seeing Carbon Upcycling cement their place in the industry and builds immense – some might say concrete – value.