The investment by Clean Energy Ventures will allow Nth Cycle to scale its metal processing technology, an alternative to pyrometallurgy and hydrometallurgy processes.

BOSTON, April 8, 2021 – Nth Cycle, the maker of a recycling technology that extracts critical metals from batteries, e-waste, low-grade ore, and mine tailings so they can be reused to make new clean energy products, today announced that it secured $3.2 million in funding from investors led by climate tech venture capital firm Clean Energy Ventures.

Nth Cycle uses an environmentally-friendly process called electro-extraction to recover cobalt and other minerals from discarded batteries and mining ores and waste using only electricity and carbon filters. Electro-extraction is a cleaner, lower-cost alternative to the conventional pyrometallurgy and hydrometallurgy processes used by battery recyclers and mining companies to recover cobalt, nickel and manganese for new battery manufacturing. This technology expands the circular supply chain of critical minerals for the clean energy transition.

“As demand for batteries increases dramatically in the coming decades, we need a sustainable process for recycling and reusing critical minerals to build a secure, low-cost domestic supply chain for electric vehicles and energy storage that avoids imports from unreliable and politically unstable regions,” said Daniel Goldman, Managing Director at Clean Energy Ventures. “Nth Cycle’s best-in-class technology reduces the volume of e-waste headed for landfills, improves the effectiveness of existing mines, and can ultimately have a material impact on climate change by mitigating over 2.5 billion tons of CO2e emissions over the next thirty years through cleaner processing and re-use of critical minerals.”

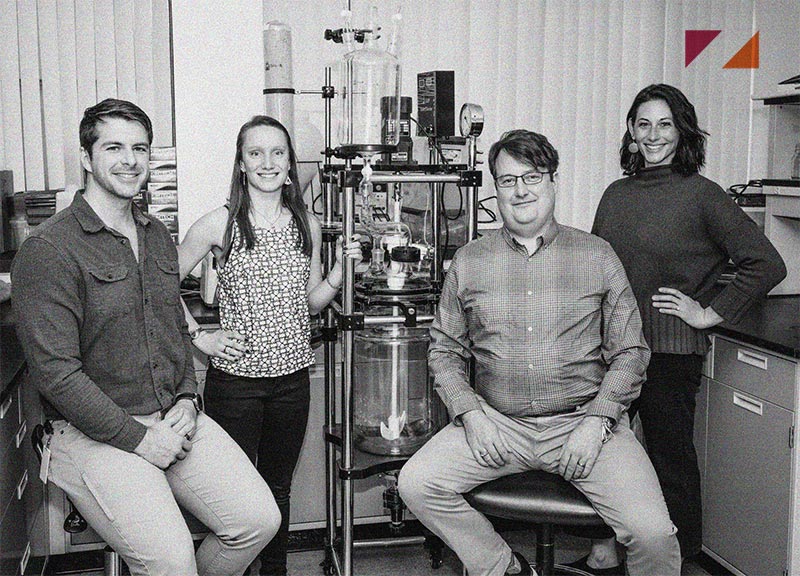

Nth Cycle, whose technology was developed at Harvard University and Yale University, recently opened new operations in the Boston area, and will use the funding to execute their technology roadmap and deploy several pilot projects with recyclers and mine operators early next year. The company has seen extensive interest in its technology from battery recyclers, operators of existing and proposed mines, auto OEMs and micro-mobility companies, and battery manufacturers eager to utilize this technology to reduce reliance on imported critical metals or environmentally unfriendly recovery technologies.

“Separating critical minerals from other metals in the recycling and mining process can be costly and complex”, said Daniel Miller, Innovation Crossroads Program Lead at Oak Ridge National Laboratory. “A technology like Nth Cycle’s reduces the cost, footprint, and environmental impact of producing recycled metals that have exactly the same composition and performance as newly mined minerals.”

“A significant fraction of the critical minerals needed for the transition to electric vehicles are already in circulation today, we just haven’t had a clean, profitable way of retrieving them, until now,” said Megan O’Connor, CEO and Founder of Nth Cycle. “Through electro-extraction, we’re turning waste into valuable resources and we look forward to bringing this technology to battery recyclers and miners so we can all move together on a path toward a more sustainable planet.”

About Nth Cycle

Nth Cycle is a metal processing technology company. We work with battery recyclers and miners to recover production-grade critical minerals from separated e-waste and low-grade mine tailings. Our electro-extraction technology—an alternative to hydrometallurgy and pyrometallurgy—enables customizable, clean and consistent recovery of the critical minerals for the energy transition. Learn more at nthcycle.com.