Ammonia is a simple molecule – NH3, one atom of nitrogen bonded to three atoms of hydrogen – but it’s one of the world’s most important chemicals. Ammonia is the primary feedstock for fertilizers, used across chemical processes, and a precursor to explosives. The history of ammonia centers around the Haber-Bosch process, a chemical process now over one hundred years old, which enabled scientists and engineers to synthesize ammonia from just nitrogen gas (N2) and hydrogen gas (H2).

Man-made synthesis of ammonia changed the course of history: Agriculture was no longer dependent on mining natural (and limited) deposits of guano or nitrates from remote coastal areas in Chile or Peru – ammonia could be made in industrial cities anywhere in the world. For over a century, man-made synthesis of ammonia unlocked unprecedented population growth, and we now make 180 million tons of ammonia every year, 70% of which is used for fertilizer production. In fact, roughly half of the world’s population today is fed by synthetic ammonia fertilizer.

However, two challenges exist with the classic Haber-Bosch process. First, the process relies on hydrogen gas as a feedstock, which is almost exclusively produced from fossil fuels and releases CO2 as part of the process. Current ammonia production results in two tons of CO2 released for every one ton of NH3 produced, and emissions are even higher where coal is used as a feedstock.

Second, ammonia production is centralized in large megascale plants, producing millions of tons of ammonia per year, but then needs to be transported to end users via ships, trains, and trucks, which can add significant cost, complexity, and carbon emissions. The high temperature, high pressure Haber-Bosch process favors production in large chemical plants, where economies of scale dominate.

A novel electrochemical method for ammonia production

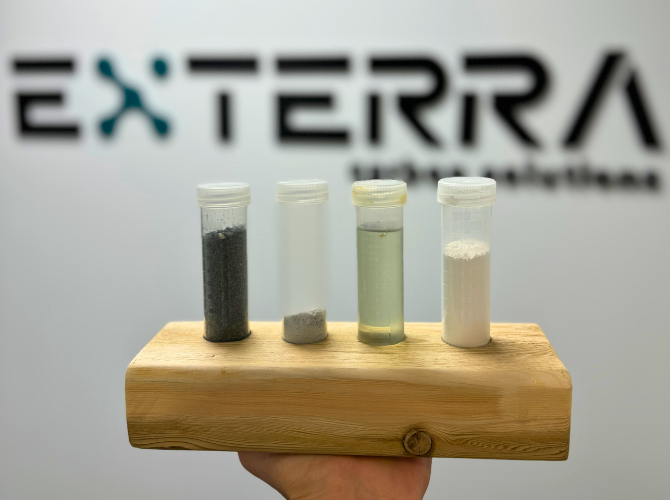

Nitrofix addresses both these challenges – a revolutionary technology that produces ammonia directly from electricity, nitrogen gas, and water. The company has found the holy grail of ammonia synthesis: a catalyst that enables ammonia production in a one-step electrochemical process, which can be powered by renewable electricity and operates at low temperatures and pressure. This process also does not require any hydrogen gas as a feedstock or intermediary (hydrogen atoms are pulled directly from water), therefore simplifying ammonia production.

The technology comes from the renowned Weizmann Institute in Israel, and the team is led by experienced professionals: Ophira Melamed, Meital Alon, and Yehuda Borenstein, with extensive support from Prof. Ronny Neumann at the Weizmann Institute. Our diligence team were impressed by Nitrofix’s deep technical expertise, industry experience and knowledge of electrochemical cells. Nitrofix’s technology is compelling for its simplicity of deployment, inherent low energy requirements, and potential for business model innovation.

Electrochemical ammonia synthesis has proven challenging because N2 is a highly stable molecule owing to the triple bond between the two nitrogen atoms. Typically, significant extra energy (overpotential) is needed to split N2 and synthesize ammonia at an industrially useful rate. In addition, hydrogen atoms, which are necessary to make NH3, can react electrochemically to make H2 gas, which is energetically favored over ammonia production. The key to Nitrofix’s innovation is a catalyst and reactor that are selective enough to produce ammonia and not hydrogen, while doing so with low energy losses.

Distributed ammonia production creates supply closer to the point of use, improving supply chain resiliency and reducing transportation emissions. Nitrofix’s technology requires only three widely available inputs: electricity, water, and air, and can be easily co-located alongside renewable energy generation, utilizing low-cost green electricity to produce a valuable and versatile commodity chemical.

A cleaner future and a growing market

Carbon emissions from ammonia production currently account for 2% of total global emissions, and new technologies like Nitrofix present cost effective ways to decarbonize an existing carbon intensive industry. Furthermore, green ammonia production could help to decarbonize hard-to-abate sectors, like maritime shipping or heavy duty transportation. Ammonia is also an effective hydrogen carrier, and can be ‘cracked’ to hydrogen gas or directly combusted for power generation. Experts forecast the ammonia market will grow at five percent per year through 2050, given new applications and uses for ammonia as an alternative fuel source.

With Nitrofix, we’re excited to invest in a company that can decarbonize an existing dirty industry, and further help to decarbonize other hard-to-abate sectors.