We were promised a circular future, a world where our discarded plastics and textiles would be reborn. Instead, we’re drowning in a linear tide of waste, a broken system of recycling masquerading as progress. Mechanical recycling, which relies on shredding and melting plastics, physically damages the polymer chains, shortening them and weakening the material until it’s unusable fibers. Chemical recycling, while aiming to restore plastics to their original state by breaking them down into monomers, requires high energy and chemical processes and the additional step of repolymerizing those monomers back into usable polymers, making it both energy-hungry and costly, drastically exceeding the cost of virgin plastic production. The result? A dismal 9% global recycling rate, and ever-growing mountains of textile waste. The truth is stark: this path towards circularity is a dead end, and scalable and economical innovations need to play a major role in fixing this problem.

The limitations of current recycling methods are reflected in polyethylene terephthalate (PET), a staple material in bottles and textiles. Major brands like Coca-Cola, PepsiCo, and Adidas face mounting pressure from consumers and regulators alike to meet ambitious sustainability targets. This is driving a surge in demand for recycled PET and polyester. Yet even the most novel chemical recycling approaches, like glycolysis and methanolysis, still involve the costly process of breaking down PET into monomers and then repolymerizing them. Furthermore, they struggle to handle low-value PET, such as heavily colored flakes and textiles. This creates a highly competitive market for relatively clean feedstock, leaving a significant portion of readily available resources as waste.

MacroCycle’s Revolutionary Approach: Whole Polymer Upcycling

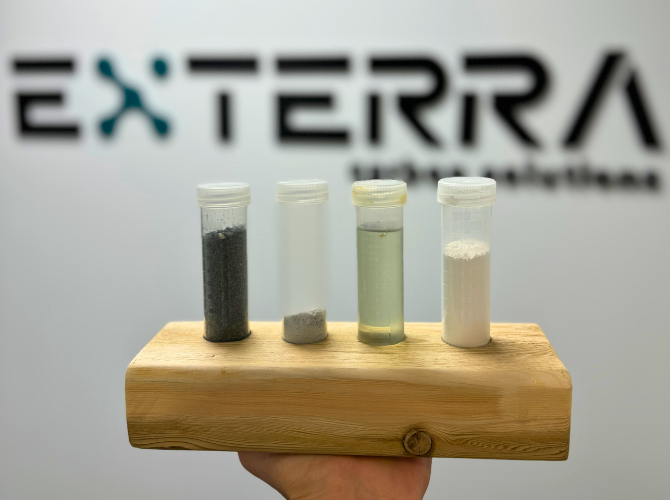

MacroCycle Technologies, founded by Stwart Peña Feliz and Jan-Georg Rosenboom, provides a compelling solution to this challenge. They’ve developed a groundbreaking chemical recycling technology that overcomes the limitations of existing methods. Instead of the energy-intensive process of breaking PET into monomers, MacroCycle uses a unique solvent-catalyst mixture at moderate temperatures to dissolve the polymer in its entirety. Remarkably, their process even extends the polymer chains by connecting the linear plastic polymers into cyclic oligomers (macrocycles) intermediates. They then force macrocycles to undergo Ring Opening Polymerization (ROP) to create longer polymer chains compared to the starting material to reach an upcycled state. This innovative approach eliminates the need for costly and energy demanding depolymerization and repolymerization steps as they never undo the energy that went into making the original polymer.

Here’s the key differentiator: MacroCycle’s technology represents a true breakthrough in PET recycling. It delivers genuine upcycling, transforming a wide range of waste, from low-grade flakes to poly-cotton textiles, into virgin-quality PET and polyester pellets. This achievement is driven by their ability to preserve and enhance polymer chain lengths, ensuring no loss in material integrity. Crucially, their simplified process eliminates the need for energy-intensive depolymerization and repolymerization, enabling smaller, more localized recycling systems that slash energy use by up to 80%. This is not just recycling; it’s a fundamental shift in how we handle PET waste.

Why Clean Energy Ventures Invested in MacroCycle

Clean Energy Ventures invested in MacroCycle because we recognize the transformative potential of their technology and the exceptional capabilities of their founding team.

Several key factors drove our decision:

- Game-Changing Technology with Real Impact: MacroCycle’s innovative approach to PET recycling represents a significant advancement. Their ability to upcycle low-value PET waste into virgin-grade material with minimal energy input is truly transformative. We see this as a paradigm shift, not just an incremental improvement.

- Explosive Market Growth: The demand for recycled PET and polyester is rapidly expanding, driven by consumer pressure and evolving regulations. MacroCycle’s technology is ideally positioned to capitalize on this growing market, offering a solution that is both sustainable and economically viable.

- Visionary Leadership: Stwart Peña Feliz and Jan-Georg Rosenboom bring a powerful blend of technical expertise and entrepreneurial drive. Stwart’s knack for business development, combined with Jan-Georg’s experience as a leading polymers innovator, provides a strong foundation to scale both the business and technology. We were particularly impressed by their clear vision and execution capabilities.

- Exceptional Investment Partnership: Investing as co-leads alongside Volta Circle, an investment firm backed by the founders of global PET producer and recycler Indorama Ventures, we have deep insights to the technical, market, and talent requirements of scaling a recycling business. This strategic partnership strengthens MacroCycle’s position and accelerates its path to market leadership.

- Significant Climate Impact: MacroCycle’s low-energy process has the potential to significantly reduce greenhouse gas emissions associated with PET production. By providing an economically viable alternative to virgin PET, MacroCycle could make a tangible difference in combating climate change. This aligns perfectly with Clean Energy Ventures’ mission to support technologies that accelerate the clean energy transition.

MacroCycle’s technology directly tackles the core challenges of plastic and clothing recycling by offering a truly circular and economically viable solution. We are excited to partner with MacroCycle on their journey to revolutionize PET recycling and create a more sustainable future. This isn’t just an investment; it’s an investment in a cleaner, more circular economy.