Our global economy is facing the simultaneous need to: (1) reduce carbon emissions use across industries and (2) pull CO2 out of the atmosphere at the scale of Gigatons per year. While electrification if cost effective could meet the lion’s share of addressing the former issue, there is a clear need for technologies that can address the latter issue of providing economically-viable carbon dioxide removal (CDR) solutions today especially considering that a business-as-usual scenario would exhaust the remainder of the carbon budget in less than ten years. As such, durable CDR solutions are an indispensable lever for achieving net zero GHG emissions to reach the Paris Climate Agreement goals, and can also spur additional market commitments as we recently witnessed with Frontier’s $925M carbon removal Fund.

Projected Carbon Abatement and Removal to Stay Within 1.5C Increase

However, many forms of direct air capture (DAC) are nascent, not only facing the challenge of technological and commercial-scale deployment but also an undeveloped carbon market currently unable to fully support this ecosystem. Current DAC costs are about 2-6x times higher than economically viable, and this varies depending on the source of energy used. In addition to capture cost hurdles, both the verifiability and durability of the sequestered CO2 remain barriers to ensuring that these molecules are actually captured AND stored away (for which there are additional costs) on time horizons that can materially reduce the stock of atmospheric CO2. As a result, the utilization market, as opposed to storage, is only just developing now, as it is difficult for technologies to create economic value from carbon molecules without a supportive regulatory environment, as well as prove the additionality of their activities.

Travertine Technologies has developed an electrochemical platform that reduces emissions from chemical production, recycles environmentally harmful waste, and turns atmospheric CO2 into minerals

This value proposition motivated the recent joint investment between CEV and Grantham Environmental Trust for a $3M seed round for Travertine Technologies. The company has developed an electrochemical platform that produces carbon-negative chemicals, performs DAC through CO2 mineralization, and recycles chemicals to reduce environmental harm. At its core, this technology uses an acid-base chemistry to produce sulfuric acid, which can aid in the extraction of critical elements (e.g. lithium for EVs and phosphorus for fertilizer), while precipitating carbonate minerals, essentially mimicking geological processes that regulate global atmospheric carbon dioxide concentrations.

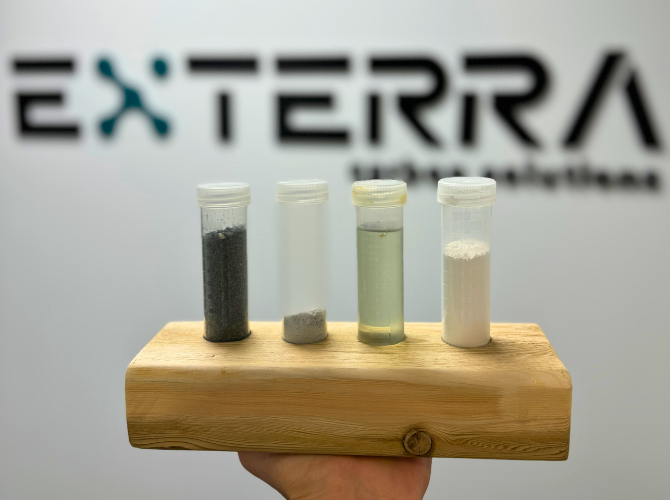

Today, many critical industrial processes such as claystone lithium extraction and fertilizer production rely on sulfuric acid that is traditionally produced by oxidizing elemental sulfur, a byproduct of oil refining and oil sands upgrading. However, Travertine’s technology allows it to avoid fossil fuel inputs altogether, as its electrochemical process converts atmospheric CO2, locally-sourced gypsum or sulfate waste, and renewable electricity to generate its primary product, sulfuric acid, as well as hydrogen, carbonate minerals, and oxygen as byproducts. The market for Travertine’s product is immense and only continues to grow, as sulfuric acid is the most-used chemical in the world, with annual global production levels at 200-300 million t/yr, Lithium mining companies have seen sulfuric acid become one of the largest, if not the biggest, operational cost – especially as traded sulfuric acid prices have jumped from $135/t to over $200/t within the last year.

In addition to producing cost-competitive sulfuric acid, Travertine’s production process doubles as a carbon sequestration process. With projected lower costs of renewable energy in the future, the sulfuric acid production alone could be profitable enough to enable a profitable plant, excluding any benefits of carbon credits. On top of that, Travertine’s acid-base chemistry enables critical mineral extraction while also sequestering carbon at a gigaton scale as it accelerates the carbonate mineralization process that typically happens on geological time scales. This carbon-sequestering process can use either newly-mined gypsum or the aqueous sulfate waste streams generated during extraction, allowing sulfates to be recycled. This leachate recycling process reduces magnesium sulfate waste generation through a highly efficient and low energy intensity process, allowing Travertine to extract even more value from the same amount of ore while using the same technological platform.

Travertine stands out as a business that can successfully sequester Gigatons of carbon without sacrificing economic viability. With both lithium and fertilizer markets experiencing skyrocketing input prices in the face of increased demand and uncertain supply, the current market environment (and prospects for the future) is one that provides ample opportunity for Travertine to enter with a solution that is both cost competitive and carbon negative.

The Travertine electrochemical platform has potential for many other operational benefits and future revenue streams

In addition to producing sulfuric acid for use in lithium extraction, Travertine is pursuing several other applications of its technology in large markets. Travertine is partnering with fertilizer production companies to use its process to turn a waste product of fertilizer production into sellable products. The traditional production of phosphorus fertilizer results in huge quantities of phosphogypsum waste. This waste material is piled near fertilizer plants and can leach both phosphorous and radioactive elements into the groundwater. Travertine’s process can use the waste phosphogypsum as a feedstock in its CDR process to convert the phosphogypsum to green hydrogen and calcium carbonate, sequestering carbon dioxide from the air. Their process can reduce a huge liability for fertilizer production companies while sequestering carbon dioxide and producing sellable products.

Travertine is also participating in the nascent voluntary carbon removal market. Large corporations such as Microsoft, Shopify, Stripe, and many others have made commitments to offset their emissions by purchasing carbon dioxide removal. Travertine’s process permanently sequesters carbon dioxide as a carbonate mineral making their carbon credits highly durable and valuable in the voluntary market. Stripe, via its new joint fund Frontier with Meta, McKinsey and others, recently made an advance purchase from Travertine.

Travertine’s team provides the competitive edge for continued innovation and scaling of this technology

Professor Laura Nielsen Lammers and Owen Cadwalader are the visionaries behind this technology, taking this novel electrochemical process from Prof. Lammers’ lab and purpose-fitting it for commercial use as a widespread decarbonization solution. As one of the leading scientists in carbonate mineralization, Prof. Lammers is Travertine’s CEO, with extensive background in this field and research experience at both UC Berkeley and Lawrence Berkeley National Lab. Joining her as COO is Owen Cadwalader, whose former roles include VP at CleanSpark, as well as roles at Molekule, Opti and Geosyntec Environmental Engineering. His prior experience in bringing technologies from the lab to market, and scaling companies will be critical for Travertine as it enters its commercialization stage.

Thus far, the Travertine team has successfully completed bench tests at UC Berkeley to identify optimal operating conditions and constrain unit economics based on measured energy intensity. Going forward, capital from this seed round will be used to expand their team, to establish an R&D lab to scale up their technology, and to work with strategic partners to build a pilot-scale plant.

CEV is excited to have invested in a promising technology that addresses the ever-increasing demand for lithium, the greater need for a greener refining process, and the stark reality that economically viable carbon dioxide removal solutions are needed now rather than later. We hope Travertine is the first of many well-funded technologies that provide financially and environmentally robust solutions for simultaneously accelerating decarbonization in current processes and sequestering atmospheric carbon.