Led by Clean Energy Ventures, the seed round is composed of an experienced consortium of new and returning investors across the climate tech ecosystem

Oakland, Calif., June 13, 2024 — Aepnus Technology, the developer of an electrochemical platform to improve circularity and reduce emissions in battery supply chain chemicals, raised $8 million in seed financing to accelerate the production of their novel end-to-end sodium sulfate recycling technology. The round was led by Clean Energy Ventures with participation from Voyager Ventures, Lowercarbon Capital, Impact Science Ventures, Muus Climate Partners and Gravity Climate Fund. Aepnus will leverage the funding to deploy pilot systems with customers across the battery supply chain, including critical minerals refineries, battery manufacturing plants and battery recycling facilities.

The lithium-ion battery supply chain produces millions of tonnes of sodium sulfate waste every year, which is disposed in domestic and international landfills. As demand for batteries continues to rise, battery manufacturers are facing the headache of what to do with this vast volume of waste while maintaining access to critical input chemicals such as sodium hydroxide and sulfuric acid.

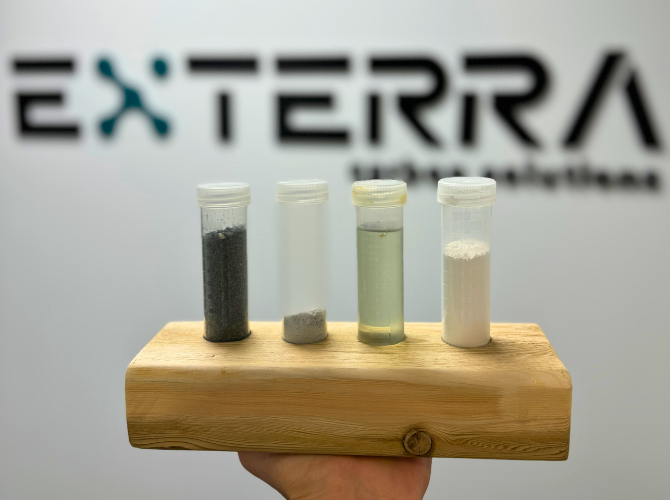

Aepnus addresses both challenges through a highly efficient, scalable electrolysis platform that converts sodium sulfate waste back into sodium hydroxide and sulfuric acid, two of the battery industry’s essential input chemicals. Inspired by the two founders’ research on electrochemical water desalination at Lawrence Berkeley National Laboratory, Aepnus’ advanced electrolysis process is 50% more energy efficient than traditional electrolysis processes and does not require expensive components made of rare earth elements such as Iridium. This competitive advantage enables the company to achieve market-leading unit economics valorizing an industry waste product.

Aepnus will be the first and only provider of an end-to-end, low-cost sodium sulfate recycling solution in the world, delivering battery supply chain customers access to crucial chemicals that are cost-competitive, produced locally and carbon-neutral. Aepnus plans to expand its technology platform to produce a host of other commodity chemicals over the next five years. Through its technology, Aepnus will mitigate a projected 3 gigatons of greenhouse gas emissions by 2050.

“The disposal of waste produced throughout the supply chain is a fundamental challenge to the scale-up of the domestic battery industry for mobility and the grid,” said Daniel Goldman, Co-founder and Managing Partner of Clean Energy Ventures. “Led by a promising team, Aepnus brings a sustainable alternative to today’s high-cost and energy intensive solutions on the market. We’re eager to help the company as it scales its technology to decarbonize global battery manufacturing processes.”

“Aepnus turns the battery industry’s biggest waste problem into a profit powerhouse,” said Lowercarbon Capital Partner Christina Chang.

“The close of our seed round marks another milestone for Aepnus. We’re delighted to have an exceptional syndicate of investors onboard with unparalleled track records scaling the most innovative and impactful climate technologies on the market today,” said Lukas Hackl, CEO of Aepnus. “Our investors’ market expertise will be crucial as we double down on our growth strategy in the coming months to decarbonize of the battery supply chain.”

As part of the financing, Clean Energy Ventures’ Venture Partner, Mallika Gummalla, PhD, will join the Board of Directors. Gummalla is a seasoned technologist responsible for pioneering new materials, new technology platforms and new solutions in the electrochemical industry.