The global transition to clean energy is accelerating, and at its core lies a surging demand for lithium—a critical component in lithium-ion batteries powering electric vehicles (EVs) and energy storage systems. With batteries projected to account for 95% of lithium needs (up from 70% today), estimates forecast a staggering 12-fold increase in demand through 2040-2050 according to McKinsey. Meeting this demand will require lithium production to scale up to approximately 11.2 million tons annually by 2050 (Benchmark Mineral Intelligence).

Despite this expanding demand, the lithium supply chain faces significant challenges. Environmental concerns, geopolitical risks, and technical limitations in extraction methods threaten the stability and sustainability of lithium production.

Challenge 1: Environmental and Geopolitical Risks in Lithium Production

The majority of the world’s lithium brine supply is concentrated in the salt flats of Argentina, Chile, and Bolivia—collectively known as the “Lithium Triangle.” This region holds nearly half of the world’s lithium resources, estimated at 50 million tons. However, traditional lithium extraction methods used here are both water-intensive and environmentally taxing. They consume vast amounts of scarce freshwater and employ harmful acids, posing significant threats to local ecosystems and communities in these arid regions.

Furthermore, geopolitical uncertainties in Argentina and Chile could disrupt lithium production. Issues such as resource nationalism and regulatory changes may deter foreign investment and compromise operational stability.

Challenge 2: Domestic Obstacles to Onshoring Lithium Production in the United States

In response to these global challenges, the recent discovery of substantial lithium reserves within the United States, along with commitments from the U.S. Department of Energy to support developments like Nevada’s Thacker Pass—the largest known lithium deposit in the country—present a significant opportunity to onshore the lithium supply chain.

However, mining, refining, and processing lithium domestically still face considerable hurdles:

- Environmental Regulations: The United States enforces stringent environmental standards to protect ecosystems and public health. While these regulations are essential, they can prolong permitting processes and increase compliance costs for mining projects. Environmental concerns and legal challenges have delayed new mining operations, making it difficult to rapidly scale domestic production.

- International Competition: Established lithium-producing countries benefit from advanced infrastructure and easily accessible resources. Their dominance in the global market makes it less attractive for new entrants—including those in the U.S.—to invest heavily in extraction projects that may not be cost-competitive.

These obstacles highlight the need for innovative solutions that can overcome environmental and economic barriers, making domestic lithium production both viable and competitive on a global scale. This is where Lithios comes into play.

Lithios’s Solution: Advanced Lithium Extraction (ALE)

Lithios, founded by Dr. Mo Alkhadra—a PhD in Chemical Engineering from MIT—and supported by Chief Scientist Prof. Martin Bazant of MIT, has developed an electrochemical approach for ALE. This groundbreaking technology enables lithium to be extracted from brines at lower costs, with reduced energy and water requirements, and without chemicals.

Lithios, founded by Dr. Mo Alkhadra—a PhD in Chemical Engineering from MIT—and supported by Chief Scientist Prof. Martin Bazant of MIT, has developed an electrochemical approach for ALE. This groundbreaking technology enables lithium to be extracted from brines at lower costs, with reduced energy and water requirements, and without chemicals.

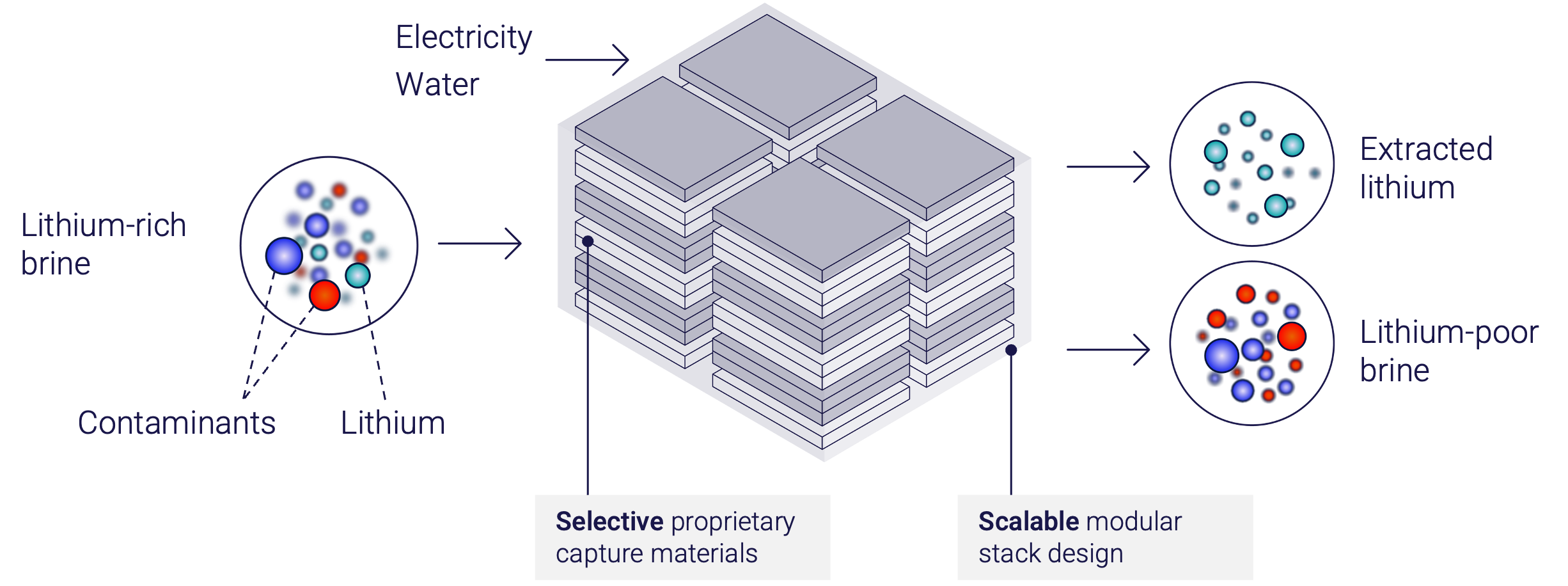

Lithios’s electrochemical reactors operate like a battery cell, with a stack of electrodes assembled in arrays. These reactors selectively capture lithium ions from flowing brines into battery cathode materials. The lithium is then released into clean water through a rinsing process. This method not only reduces freshwater consumption dramatically but also eliminates environmental hazards and supply chain challenges associated with acid or solvent use.

Why Lithios Stands Out in the Lithium Triangle

Lithios’s technology directly addresses the environmental concerns in the Lithium Triangle by significantly cutting water usage—a massive advantage for freshwater-constrained brine deposits. By reducing freshwater and energy requirements compared to ion exchange and adsorption methods, Lithios minimizes the environmental footprint of lithium extraction. This sustainable approach can alleviate local tensions over water resources and help preserve delicate ecosystems.

Furthermore, Lithios’s ability to process lower-grade brines unlocks additional lithium reserves previously deemed uneconomical. This expands the potential supply without exacerbating environmental degradation, offering a solution that is both economically viable and environmentally responsible.

The Appeal of Electrochemical Approach Over Ion Exchange and Adsorption

Traditional direct lithium extraction methods like ion exchange and adsorption involve multiple chemical steps, significant energy consumption, and substantial freshwater use. These processes often require large capital expenditures and have limitations in selectivity and efficiency.

Lithios’s electrochemical approach offers several advantages:

- Selectivity and Efficiency: The technology selectively captures lithium ions, improving purity and reducing the need for extensive downstream processing.

- Lower Energy Consumption: The electrochemical process is inherently more energy-efficient, reducing operational costs.

- Reduced Environmental Impact: By eliminating acid use and drastically cutting freshwater requirements, the process is more sustainable.

- Modularity and Scalability: The reactors are modular and fit into standard process trains, allowing for scalable deployment and integration into existing facilities.

Unlocking Domestic Lithium Production with Lithios

Lithios’s advanced lithium extraction technology provides a groundbreaking solution to the challenges that have hindered domestic lithium production in the United States. By directly addressing cost competitiveness, stringent environmental regulations, and international competition, Lithios makes domestic lithium extraction both feasible and economically attractive.

- Enhancing cost competitiveness through its low-cost, low-capital-expenditure electrochemical approach. This method significantly increases energy efficiency and lowers freshwater requirements compared to traditional extraction techniques. The modular design of their reactors allows for scalable deployment, lowering initial investments and enabling producers to achieve economies of scale more rapidly.

- Minimizing ecological impact and aligning with tougher environmental regulations. Lithios’s electrochemical process eliminates the need for harmful acids and drastically reduces freshwater consumption, addressing major environmental concerns associated with lithium extraction. This environmentally responsible approach could simplify the permitting process and reduces compliance costs, expediting project timelines and enhancing community acceptance.

- Enabling U.S. producers to tap into previously uneconomical or lower-grade lithium brine resources, including geothermal and oilfield brines. By unlocking these domestic reserves, the United States can diversify its lithium supply and reduce dependence on imports. This positions U.S. producers to compete more effectively in a global market dominated by established players.

Why Clean Energy Ventures Invested in Lithios

At Clean Energy Ventures, we are committed to backing companies that offer scalable solutions to the world’s most pressing energy challenges. Our investment in Lithios is grounded in several key factors:

- Innovative Technology with Environmental Benefits: Lithios’ ALE technology represents a significant advancement in lithium extraction, addressing both cost and environmental issues associated with traditional methods.

- Strong Technical Team: CEO Dr. Mo Alkhadra brings deep expertise from his academic background, and with Professor Martin Bazant as Chief Scientist, the company is anchored by leading minds in chemical engineering and electrochemistry.

- Market Opportunity and Impact: With lithium demand set to increase exponentially, Lithios is positioned to meet this need sustainably, contributing to the broader adoption of EVs and renewable energy storage—key components in reducing global greenhouse gas emissions.

- Geopolitical Risk Mitigation: By enabling efficient lithium extraction from previously untapped resources, including those in the United States, Lithios helps diversify the global supply chain and reduce reliance on geopolitically sensitive regions.

Revolutionizing Lithium Extraction for a Sustainable Future

Lithios is at the forefront of a revolution in lithium extraction, offering a solution that aligns with our mission to accelerate the transition to a clean energy future. Their technology not only addresses the urgent environmental and geopolitical challenges facing lithium production but also paves the way for a more sustainable and secure supply chain.

Our investment reflects our confidence in Lithios’s potential to make a substantial impact on the energy industry and our commitment to supporting innovations that drive environmental progress. We are excited to work alongside Lithios as they scale their technology and contribute to a cleaner, more sustainable world.

Visit Lithios’s website to learn more or contact Wynston Reed for an intro to the team.