The hydrogen dream

Low carbon hydrogen will play a critical role in our efforts to decarbonize our economy. Industry experts may debate which sectors are most suited for hydrogen, but the breadth of applications indicate increased demand for hydrogen, whether for green steel, heavy-duty transportation, green chemicals and ammonia, sustainable fuels, power generation, and energy storage. A future with hydrogen promises a world in which industry emits no greenhouse gases, and no toxic particulates spew from smokestacks. Analysis for clean hydrogen demand in a 2050 net zero scenario forecasts a 6x increase, reaching 600Mt tons of H2 produced every year.

The vast majority of investment and research has been focused on hydrogen production – whether for green, blue, turquoise, or white hydrogen – but comparatively little attention has been paid to hydrogen storage and transportation. The oversight is understandable: hydrogen is notoriously hard to transport and store. In the gas phase, H2 escapes easily and causes embrittlement for metal pipes. Gaseous H2 can be compressed for transportation in tube trailers, but volumetric energy density is very low (approximately 10% of diesel); liquid H2 has to be cooled to -253C (just 20C warmer than absolute zero!), which takes an enormous amount of energy to condense and stay condensed.

In the face of such challenges, many decarbonization approaches focused on utilizing hydrogen at point of production to circumvent storage and transportation. However, co-location of production and utilization has significant limitations: hydrogen is often needed in locations where low-cost, abundant electricity is not available. The locations where we expect low-cost renewable hydrogen to be produced (e.g., Saudi Arabia, Australia, Chile) are not the same areas as where there is existing demand for low-carbon hydrogen (e.g., Japan, Europe, South Korea). This problem could be more pronounced for white (or geologic) hydrogen, where hydrogen may be found in remote locations around the world, and most likely not where it’s needed in high population or industry-dense locations.

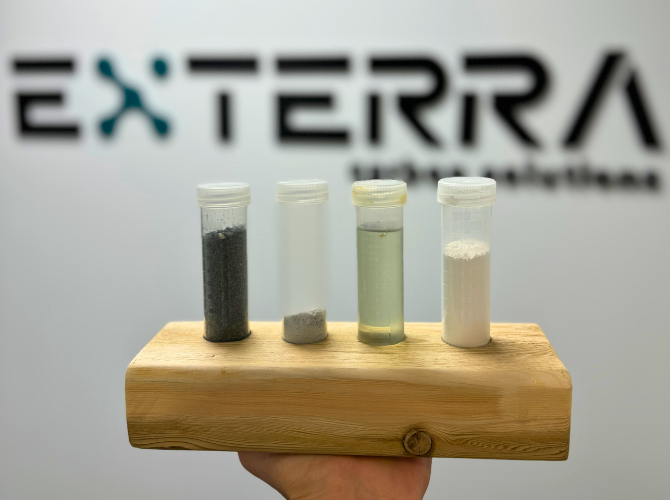

Alternative transportation and storage solutions are needed for a hydrogen economy to reach its decarbonization potential. At CEV, we have been looking for hydrogen storage and transportation solutions across different technology paradigms, but found significant challenges with proposed solutions. Solid-state metal-organic frameworks or metal hydrides are heavy and hard to handle. Ammonia, touted not just as a hydrogen carrier but as a fuel in its own right, has significant safety and toxicity challenges. Liquid Organic Hydrogen Carriers (LOHCs) bind H2 to various liquid organic compounds (e.g., toluene and methylcyclohexane (MCH)); however, many proposed solutions have high energy requirements for dehydrogenation and need to be transported as hazardous chemicals (rather than fuels). All H2 storage and transportation solutions we evaluated fell short – until we met the Ayrton team.

Better transport through chemistry

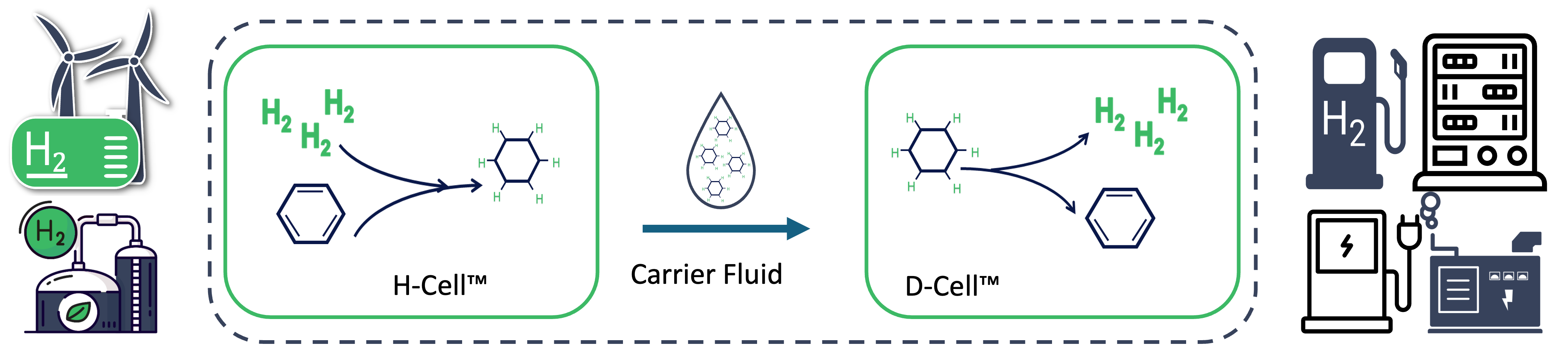

Ayrton’s “H-Cell” facility takes in hydrogen gas at the production site, and binds it to an organic molecule using a low-temperature, low-pressure electrochemical process. The hydrogenated molecule is part of a proprietary mix of other chemicals that forms a diesel-like LOHC fluid. The fluid can be transported and stored at room temperature and pressure with low toxicity and safety concerns. Upon arrival at the point of use, a “D-Cell” strips the hydrogen from the carrier molecule. The dehydrogenated carrier fluid can then be reused for more than a thousand cycles.

Unlike many other LOHCs, Ayrton’s does not require novel transportation or storage infrastructure, nor enhanced safety protocols. Their fluid can be handled as diesel fuel, so existing O&G infrastructure can be repurposed instead of rebuilt, significantly reducing capex requirements. Their solution is particularly well-suited for multi-modal applications (e.g., transporting from truck to ship to rail to truck) and their hydrogenation and dehydrogenation process is electrochemical and modular, allowing users to turn the hydrogenation and dehydrogenation process on and off, matching variability in time of H2 production and demand.

Teamwork makes the (hydrogen) dream work

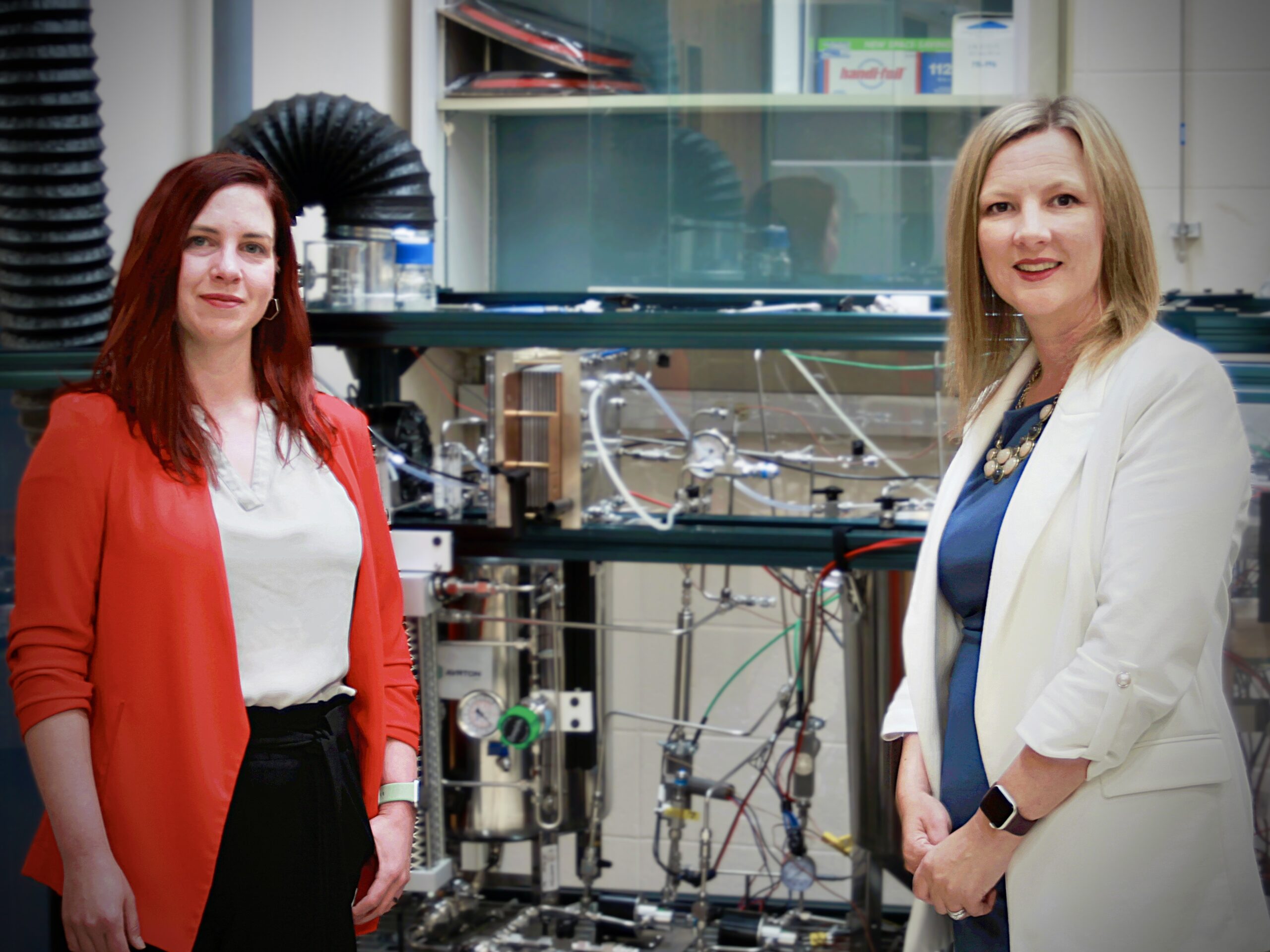

CEO Natasha Kostenuk is an engineer with over twenty years of experience in the oil and gas industry. Her work involved implementing new technologies, so she is deeply familiar with what it takes to get novel innovations from the benchtop to active service. CTO Dr. Brandy Kinkead is a brilliant chemist with over 25 peer-reviewed publications. Together, these two co-founders make an exceptional team.

CEO Natasha Kostenuk is an engineer with over twenty years of experience in the oil and gas industry. Her work involved implementing new technologies, so she is deeply familiar with what it takes to get novel innovations from the benchtop to active service. CTO Dr. Brandy Kinkead is a brilliant chemist with over 25 peer-reviewed publications. Together, these two co-founders make an exceptional team.

CEV is investing alongside a strong investor syndicate, providing Ayrton with deep technical and industry support: BDC (Business Development Bank of Canada) co-led the round alongside CEV, with additional investment from Eastern Pacific Shipping (the 4th largest shipping company globally), Antares Ventures, and SOSV. We’re delighted to be working alongside great entrepreneurs and investors to accelerate adoption of low-carbon H2 and decarbonize the most challenging sectors of our economy!

Visit Ayrton’s website to learn more or contact Yi Jean Chow for an intro to the team. Looking for a role in climate tech? Check out Ayrton’s career opportunities!